Here's the factory exhaust

still in place.

When my son Dale bought a

2008 Harley FLHTCU it didn't take him long

to ask me what he could do to the exhaust

system.

My answer, "a lot." He needed

to be more specific.There's so much a guy

can accomplish with a change, as different

systems provide different results. What we

came up with was to use a true dual system

so the appearance of the motorcycle would

not change drastically, and there's other

benefits.

The D&D Duelie pipes (part

516-22D) were chosen because they looked

good and would enhance performance by giving

the rear cylinder its own pipe providing a

true dual exhaust. Adding a set of D&D 3.5-

inch slash cut mufflers (part 408-12S) would

produce a good sound without being

offensive.

It wasn’t until I actually

received the exhaust that I saw the quality

of construction, heavy gauge of the metal,

with oxygen sensor bungs welded in place,

flawless chrome, and heat shields already

installed that I really became impressed.

Everything removed and ready

for the D&D installation.

I started off by removing the

saddlebags so everything was easy to reach.

Next move was to remove the factory heat

shield with a 5/16-1/4 drive socket (a

common screwdriver may also be used).

Using a 9/16” socket I

loosened the clamps at the mufflers and

sprayed the joints with PB Blaster

penetrating oil. While it was working I went

to the rear of the muffler and used a 1/2

inch socket to remove the two bolts from the

muffler bracket under the bags. The muffler

was removed by shaking loose and pulling on

the stuck bastards. Exhaust does nasty shit

to fasteners and connections, be patient.

I disconnected the wiring for

the Oxygen Sensors but opted not to remove

them from the pipe until I had it off the

bike. It's always a good notion to

disconnect the battery.

From the left side of the

motorcycle using a 3/8 ball end Allen, with

a extension, I removed the right floorboard

where the brackets joined the frame under

the bike. Removing the clamp on the pipe by

the transmission and the two nuts holding

the pipe to the head it came off easily.

The pipe on the left side was

removed in the same manner. It should be

noted that the bracket tab on the rear

exhaust support bracket was also removed.

There was no need to remove the exhaust

flange off the old pipes as the new pipes

have them on already. Lots of new exhaust

systems don't come with shit from the

factory, but that's not the case with D&D.

They supply most of the fasteners, spacers

for the floor boards and mufflers, the

flanges in place and the heat shields

installed. You just need the exhaust flange

nuts and new exhaust head gaskets.

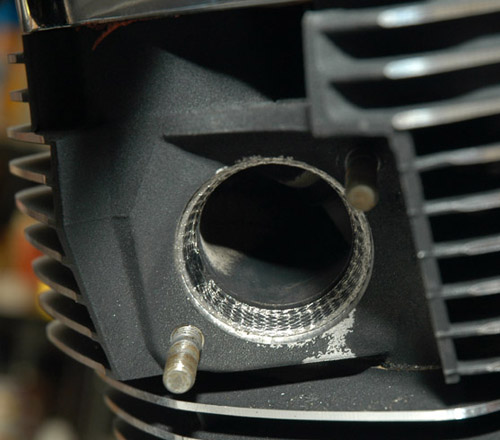

New exhaust gasket carefully

installed.

With the factory system

removed the exhaust gaskets were replaced in

the head and the Oxygen Sensors were removed

from factory pipes and installed into the

new ones. A small amount of Anti-Seize was

applied to the threads with care taken not

to get any on the sensor tip! I torqued them

to 30-44 Foot lbs.

Anti-Seize

on the tip was cleaned before sensor was

installed

The right side pipe was

fitted to the head. All the fasteners were

installed all the way to the muffler. It was

left loose and checked for position and fit

before tightening, beginning at the manifold

and working back. Then using a ˝-inch

3/8-drive socket the top nut tightened. I

was pleasantly surprised to find a cut out

in the heat shield for the bottom nut that

allowed the socket to fit without the

problems that I have experienced with other

systems. Clearances were checked and the

bottom nut on flange tightened to 100-120

inch lbs. followed by the top one to the

same specifications.

If the sensor is not

disconnected from the system, we would be

forced to twist the wire lead counter

clockwise several revolutions before

screwing it into the bung.

The tranny bracket welded to

the pipe fit the bracket on the transmission

without shimming. The muffler slid in with

ease and could be felt to bottom out on pipe

lip. The clamp was tightened enough to hold

muffler in place as the two black spacers

provided in kit were installed under the

saddle bag hanger to align the muffler with

the entire system. Some bikes need the

spacers, others don't. The bolts were

torqued to 96- 144 inch lbs while

alternating tightening. The muffler clamp

was not fully tightened at this time.

Most mechanics wear gloves to

protect their delicate skin, but Rogue does

it to protect the chrome finish.

Moving to the left side of

the motorcycle the rear pipe was installed

in the same manner as the front. I use a

piece of folded cardboard between the

transmission, primary and the pipe, to hold

the pipe in position until I install

fasteners. Once everything is in place all

fasteners are tightened from the manifold

back.

From the rear of the

motorcycle the mufflers were positioned so

they are even and then the clamps were fully

tightened. While I was connecting the wires

for the Oxygen Sensors and re-installing the

floorboard, with the spacers provide in the

kit, my helper installed the side covers and

saddle bags. A final check was made that

everything was installed and tightened

properly.

Even though I use gloves

while doing the job the pipes were wiped

clean just to make sure there wasn't

anything on them that would leave a stain

when the pipes got hot. I cure the chrome by

running the engine at idle speed for about

one minute. Let motorcycle cool and repeat

3-4 times.

Depending on your motorcycle

you may have to make some adjustments to

your fuel system. I rode the motorcycle and

was quite happy with how it sounded and

performed. I also did a sparkplug color

check and everything got a thumbs up!

I mentioned to my helper that

I do not remember the last time a job went

so well and everything fit like it was

suppose to. He had recently installed

another brand of exhaust on his bike and

said it was a lot of work to get it to fit

correctly.

To keep the pipes clean, wipe

down with Rubbing Alcohol and shine with

Glass Cleaner. DO NOT USE HARSH ABRASIVES!

When I delivered the bike to

my son, Dale, and told him to take it for a

ride, the Big Smile on his face told me we

made the right choice with a D&D exhaust.

For more information on D&D

and their products check their website

http://www.danddexhaust.com/

or contact their office at D&D Performance

Enterprises, 2923 Edith Lane, Fort Worth,

Texas, 76117. Phone 817-834-8961